plating machine

plating machine2

plating machine3

plating machine4

plating machine5

plating machine6

We are service providers and equipment suppliers, coating the back office tasks such as

wafer plating Electric Electrical (PCB) or plated work. Surface of the metal (Metal Finishing)

as well as consulting on how to improve coating machine parts to Prasit image in the making

better example. Such as improving equipment. Which is used as a term for some time.

We are consulting engineers specializing in the direct plating machines.

-Panel and Pattern

-Electro less Nickel/Gold

-Reel to Reel Plating Line

-Barrel Plating Line

-Electrodeposits Coating

-Zing Rack Plating

-Anodizing

Customer Reference

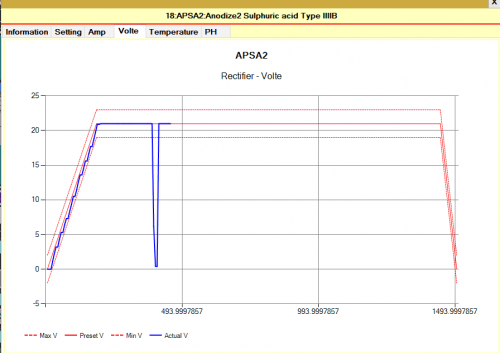

Rectifier

– We provide wide range of DC rectifier for plating machine.

– All rectifier products are high quality product come with low

ripple, low cost , easy to install and power energy saving.

– All rectifier products with fully support for automatic control system,

manual control and repairing center is locate in Thailand

Products

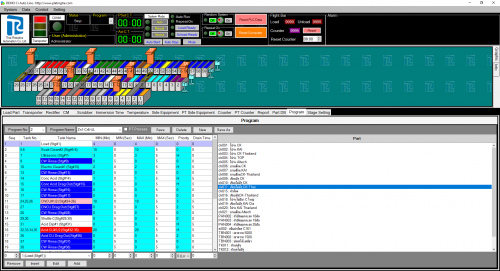

Thai Robotics and Automation is the company who develop advance automation system. During 17 years history we supply our machine to many industries. MOS (Machine operation System) is the software for machine management; it is one of our proud products. it can fit to many cyclic scheduling processes such as Plating process. We installed our software more than 20 licenses for plating machine. The advantages of our software are;

- It can run two algorithms (Fix time way or Random system).

Customer can select Fix time Way for mass production. And can select Random system for small lot Varity product. So, it suitable for Plating service industry and also for in house plating machine.

- Full automation system.

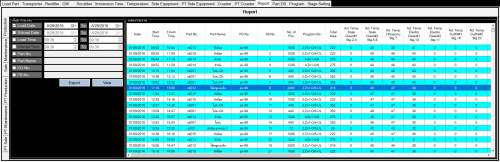

We develop the system in full automation. The machine can do Automatic rectifier control, Graph record of Rectifier output, Amp/Hour count and reduce current due to preset Amp/Hour, Automatic dosing, Automatic Load/Unload, Custom process time and sequence, Production report, Chemical usage report And more.

- Random system uses the “knowledge base and Time Priority algorithm” to find the base scheduling for each Transporter.

- Custom design.

We design the MOS software follow customer requirement. And we also can modify old machine to use our software.

- All interface can use for loading product. Barcode, RFID and Direct key in.

Process setup screen

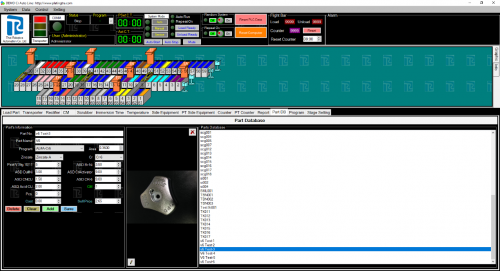

Parts Data Base

Production Report

Chemical Maintenance Report

Rectifier Output Graph